Predictive maintenance can save you money and increase safety by reducing the need for repair. This technology can detect potential problems before they happen by tracking changes in the physical condition of assets. It is a great benefit for oil and gas companies because the equipment they use can be incredibly dangerous, and predicting damage before it occurs can save them a significant amount of money.

technology enables devices

This technology enables devices to collect and transmit data about their own condition and performance. This type of service allows companies to detect equipment failures before they become costly repairs. Examples of IoT-enabled devices include smart thermostats and lights.

With IoT-based predictive maintenance, companies can prevent expensive unplanned downtime and improve productivity. By monitoring equipment in real-time, predictive maintenance can identify the causes of delays in production and set up processes to address them. This technology also enables businesses to detect equipment problems before they become serious enough to affect productivity and profitability.

The main benefit of predictive maintenance is that it helps organizations reduce the costs of unexpected failures. Having a better understanding of machine failures and how to prevent them is essential for maximizing profitability. In addition to reducing unplanned downtime, IoT-based predictive maintenance can also improve the efficiency of maintenance schedules.

Predictive maintenance is becoming an increasingly common use case in IoT. For example, a Fortune 500 industrial automation company uses Cassia Network long-range Bluetooth routers as part of their predictive maintenance solution for low-voltage motors. The use of long-range Bluetooth in predictive maintenance has become common across many industries. Moreover, Cassia Networks has active predictive maintenance use cases across a variety of verticals.

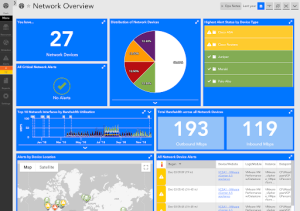

Internet of Things-based asset monitoring solutions give companies a 360-degree view of field assets, which allows them to plan and prioritize their work accordingly. This information also helps prevent unexpected downtime and the need to hire extra personnel. In many cases, unplanned downtime leads to reallocation of field service crews and rescheduling of planned maintenance activities. This kind of predictive maintenance can also improve the efficiency of field service crews by enabling better utilization of them.

Predictive maintenance can also reduce the cost of spare parts and repairs. By using AI-powered systems to analyze data, predictive maintenance can predict problems before they happen. The technology behind this technology is constantly improving and becoming more useful.

Machine learning

Predictive maintenance algorithms can be built on massive data sets. Those data sets contain detailed information about a given aircraft, including operational parameters such as temperature, operating environment, and other contextual factors. Machine learning can then perform immediate diagnosis and determine the remaining working life of operation-critical components of an aircraft.

The first step in predictive maintenance is to define the use case. Once the use case has been defined, data exploration is performed to uncover patterns in the data. These patterns can then be used to develop machine learning models. Once the model has been developed, it can be tested by comparing its performance to the expected level.

ML-based predictive approaches have the advantage of being more accurate and consuming fewer data. These algorithms can be used to predict system failure and avert it. One approach, known as classification, uses a labelled event to predict an impending failure. A similar approach, called regression, uses more data and delivers more detailed information about an impending failure.

Regression is one of the most commonly used machine learning algorithms. It is fast to implement and has an easy-to-understand output. It is typically used when the data is continuous or is within a specified range. For example, a sensor might collect data about temperature, which can be used as a continuous value.

Machine learning algorithms can automate certain tasks associated with aircraft maintenance. These algorithms can order replacement components, schedule aircraft technicians, and even generate reports and alerts. This technology can improve the efficiency of maintenance processes and reduce human error. The automation of aviation maintenance processes can also help reduce the workload of maintenance engineers. Aside from the automation of repetitive tasks, machine learning algorithms can detect anomalies that humans cannot detect.

Nondestructive testing

Nondestructive testing (NDT) is a diagnostic technique that detects defects in a product or system before they can cause a failure. This process involves measuring the amount of damage that can be caused by a flaw and calculating the probability of detection. The probability of detection increases with the size of the flaw. However, many people make the mistake of assuming that the POD of a defect is the same no matter its size. This is a mistake as POD is just one step in the analysis process. To obtain the true value of a POD, you must use statistical methods for all potential defects.

Nondestructive testing for predictive maintenance is increasingly being used in a wide variety of fields. These techniques can be used to diagnose the imminent failure of a piece of equipment, saving money on replacement. For example, vibrational analysis can detect loose parts, imbalances, misalignment, and bearing wear. Another technique is ultrasonic acoustical analysis, which uses ultrasonic sounds to assess the stress and friction in a piece of mechanical equipment.

Nondestructive testing is widely used in manufacturing, fabrication, and in-service inspections. Different methods are used for different applications, and may be better suited to specific types of applications. You should consider your specific needs and the type of component you are trying to inspect before choosing a method.

The best methods for testing are nondestructive and predictive. In both cases, the testing method should ensure the integrity of the item. By identifying where the failure is, you can determine what needs to be done to prevent future problems from occurring. By doing this, you can ensure the reliability of the item while ensuring its safety.

The most common method of NDT today is surface testing. It requires the subject to cease operation while the test is taking place. This process can be expensive, and is not ideal for safety-critical applications. The best nondestructive testing method for a safety-critical application is one that does not require downtime.

Another nondestructive testing method is eddy current testing (EDT). EDCT uses an electrical current to detect small-scale damage before it causes a failure. Moreover, eddy current testing can be used for materials research and development as well. In addition to this, eddy current testing is also useful for production quality control testing. The technique is sensitive to small cracks and subsurface defects.

Feature extraction

Feature extraction is a technique used in predictive maintenance to extract meaningful information from sensor measurements. The process of feature extraction is also known as health indicator construction and consists of designing features that aggregate sensor inputs in time-frequency-domain. Figure 2 illustrates the basic process of feature design. During the process, an alarm is generated when the health indicator exceeds the threshold (an identity function) determined by the algorithm.

Feature extraction methods are commonly used for Internet of Things scenarios, such as predicting machine failures. These models utilize deep learning technology, which reduces the dimensionality of data. The feature extraction method also reduces the need for downstream statistical models. However, it has several limitations, including time-lagged correlations among industrial sensor data.

The data at manufacturing plants are often heterogeneous, which can adversely affect the performance of ML models. The use of hand-crafted features during the feature extraction process can improve the interpretability and generalization power of the resulting models. This approach also improves the prediction accuracy and model performance.

PCA collates the information in interrelations of variables by applying orthogonal transforms.process compresses observed data to a lower dimension where the highest variance is located. Feature extraction is also useful for identifying patterns in historical data.

Feature extraction is also used in fault diagnosis. This technique uses selected features to predict the health state of machines. In traditional ML theories, a machine learning model involves data collection, feature extraction, feature selection, and health state recognition. Deep learning techniques, on the other hand, are capable of learning both the feature space and task simultaneously.